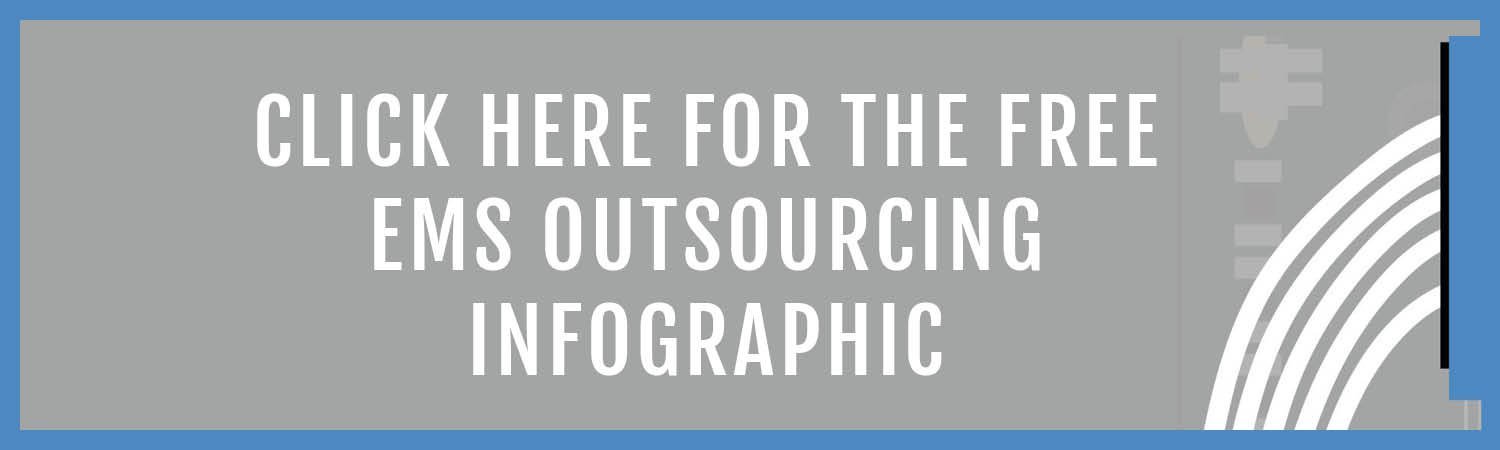

At the heart of every aspect of our business, configuration management is extremely vital to Liberty Electronics. In fact, we built our entire Enterprise Resource Planning (ERP) System around it. Expanding our Oracle Product Life Cycle Management (PLM) software to include multiple ERP functions—estimating, planning, inventory and production control, quality assurance, etc.—enabled us to embed revision management into every step of the process.

Our configuration management process consists of statuses and workflows. Statuses of sales orders, part numbers, documents, etc. can go from “In work” to “Released” to “In Change.” These mandatory shifts allow the system to prevent certain transactions until the new change has been implemented and a new “Released” version is issued. To specify effectivity, Liberty’s system utilizes “Valid From” and “Valid Until” dates. In addition, “Stop Work” is the terminology we use to prevent production while we sort out the various issues that can arise. Status histories are not only made in real time, but notifications are made automatically when statuses change. Reviews and approvals can then be conducted at appropriate times because of these notifications, which enables team members to take action based on the workflow notifications that show up in their mailboxes.

Another crucial configuration management process at Liberty is the Engineering Change Order (ECO) process. It again is Liberty-designed and is quite robust and efficient, allowing us to process a high volume of changes very quickly. All Bill of Material (BOM) changes, for example, can only be made after first changing the status and creating a new internal or external revision. In addition, engineers no longer have to manually document BOM changes; instead, the system automatically creates an “ECO BOM Comparison Report.” This report looks at the old and new revisions and lists the quantity changes, components added, and components deleted, which removes the potential for error and communicates correct details directly to our team members.

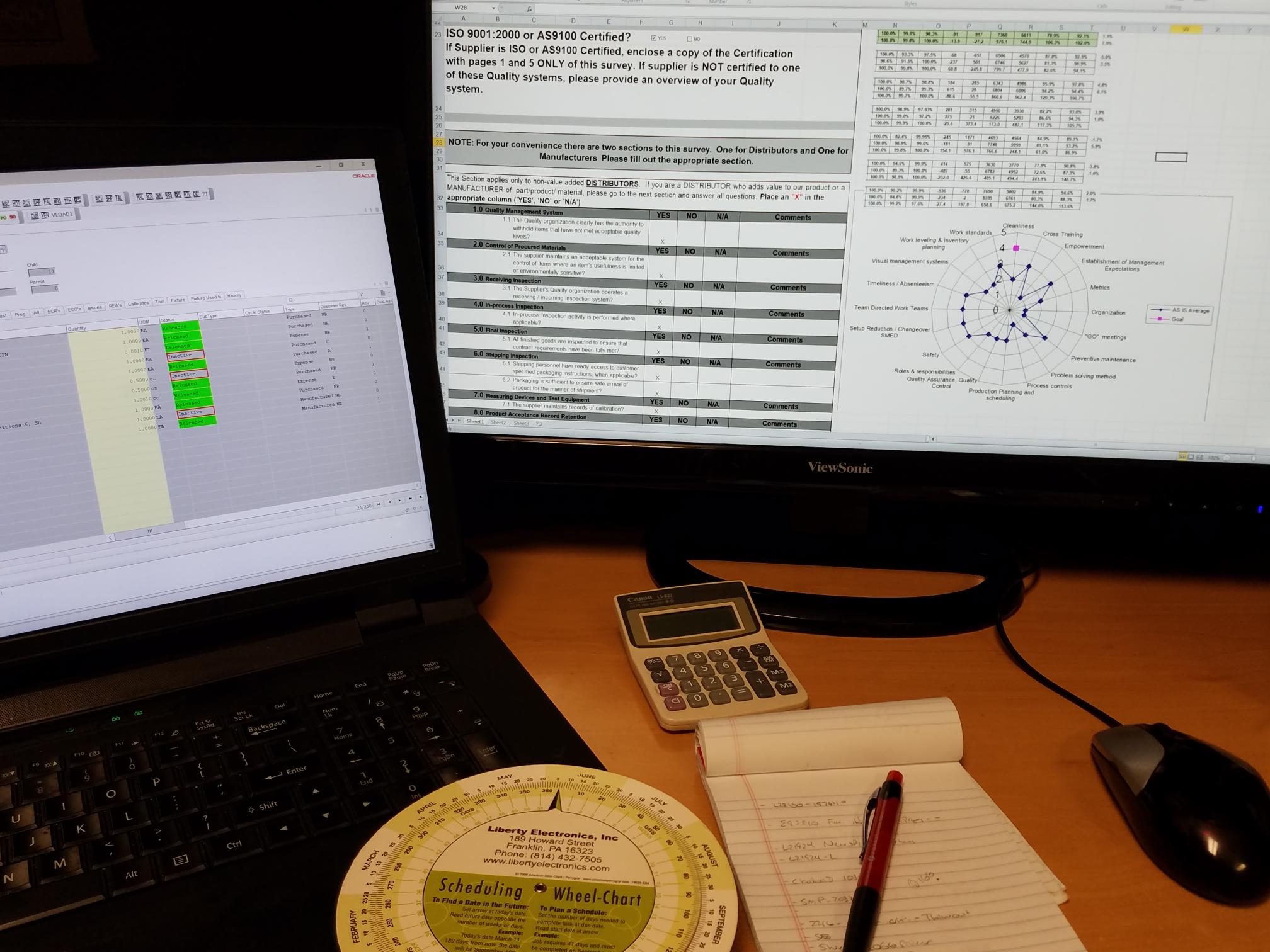

Liberty’s specific use of technology also helps the configuration management process. We exclusively utilize computer monitors and tablet devices during our production process in order to access documents. Only the approved “Released” version of the items, BOMs, routers, work instructions, etc. are available on these devices so there is no possibility for an operator to use an old revision to manufacture products, which would result in scrap, rework, and added costs. This establishes consistency within our production process and catalyzes our production process by promoting efficiency from the start of our builds.

We also keep complete histories on record of the entire life cycle of various aspects of our work processes—quotes, purchase orders, sales orders, items, BOMs, drawings, programs, routers, work instructions, etc. Transaction logs capture configuration states of assemblies during their assembly processes for posterity and communication purposes.

Configuration management at Liberty Electronic is not an additional requirement that Liberty strives to do. Instead, it is woven within our DNA; in other words, it is how we do business. Our configuration management processes allow us to guarantee that we will deliver the correct products to our customers every time.

![Liberty Electronics® Right Cable Harness Thumbnail Liberty | How the Right Contract Manufacturer Benefits OEMs [Video], Liberty Electronics®](http://blog.libertyelectronics.com/wp-content/uploads/2022/05/Right-Cable-Harness-Thumbnail-Liberty.jpg)

![Liberty Electronics® Wired Success Benefits of Collaborative Design | The Benefits of Collaborative Design [Video], Liberty Electronics®](http://blog.libertyelectronics.com/wp-content/uploads/2022/05/Wired-Success-_-Benefits-of-Collaborative-Design.png)

![Liberty Electronics® 2020 09 28 11 41 12 Benefits of a Relationship Minded Supplier Video | Benefits of a Relationship-Minded Supplier [Video], Liberty Electronics®](http://blog.libertyelectronics.com/wp-content/uploads/2022/05/2020-09-28-11_41_12-Benefits-of-a-Relationship-Minded-Supplier-Video.png)