Notice: Trying to access array offset on value of type null in /home/fqirg4uuuluu/public_html/blog.libertyelectronics.com/wp-content/plugins/js_composer/include/autoload/vc-shortcode-autoloader.php on line 64

Notice: Trying to access array offset on value of type null in /home/fqirg4uuuluu/public_html/blog.libertyelectronics.com/wp-content/plugins/js_composer/include/autoload/vc-shortcode-autoloader.php on line 64

Notice: Trying to access array offset on value of type null in /home/fqirg4uuuluu/public_html/blog.libertyelectronics.com/wp-content/plugins/js_composer/include/autoload/vc-shortcode-autoloader.php on line 64

- All

- Company Culture

- Company News

- Cost Control

- Manufacturing

- Newsroom

- Operational Efficiency

- Procurement

- Quality Control

- Supply Chain Challenges

- Wired Leadership

The Price and Prevention of Counterfeit Parts in Manufacturing

Although the aerospace industry is leading the effort to combat counterfeiting through methods like serialization tracing and supply chain control, the use and sale of counterfeit parts is still an issue in manufacturing. Counterfeiters are changing with the times too, applying more sophisticated approaches and techniques to skirt testing, laws, and standards. Blanks, clones, and undisclosed […]

Configuration Management – A Cornerstone of Liberty Electronics

At the heart of every aspect of our business, configuration management is extremely vital to Liberty Electronics. In fact, we built our entire Enterprise Resource Planning (ERP) System around it. Expanding our Oracle Product Life Cycle Management (PLM) software to include multiple ERP functions—estimating, planning, inventory and production control, quality assurance, etc.—enabled us to embed […]

Keep it Running: Tools and Company Culture

One way that a company like Liberty ensures an efficient and well-equipped workforce is by making sure the tools that employees use on a daily basis are current, calibrated, and functioning. The proper maintenance and organization of all tooling is a key element in a workforce that is confident, safe, and well-equipped. Each tool on […]

Molding and Insulation for Performance

Molding and insulation are both vital steps in protecting wire assemblies from wear and tear, allowing for a longer lasting and higher quality product. Cast molding, overmolding, and press molding are all techniques to protect the connections of a cable assembly, ensuring quality and extended use. These techniques all achieve slightly different results, while still […]

Working on Your Next Light Rail Project? Here’s What OEMs Need to Know

The global light rail industry is forecasted to reach $4.97 billion by 2026, growing at an annual rate of 9.8%. While Europe continues to maintain the highest market growth, the recent rise in light rail passengers across major U.S. cities has led to approvals for light rail extension projects throughout the country — expecting to […]

How OEMs Can Tap Suppliers To Scale Up Production

Industry predictions indicate that manufacturing will grow faster than the general economy*. Growth in areas such as global aircraft manufacturing is projected to spike from the less than 4% rise seen from 2013-2017 to nearly 9.5% from 2017 until 2021. These high manufacturing expectations are bound to cause an increase in production needs for OEMs. But how […]

Why Are Leading OEMs Choosing Turnkey Manufacturing?

Understanding Turnkey Manufacturing Turnkey manufacturing solutions are a common outsourcing practice. The term refers to outsourcing production to a single manufacturing partner who controls the process from beginning to end. Companies choose this model because it eliminates the hassle of managing relationships with multiple vendors, making it is as simple as “turning a key” to […]

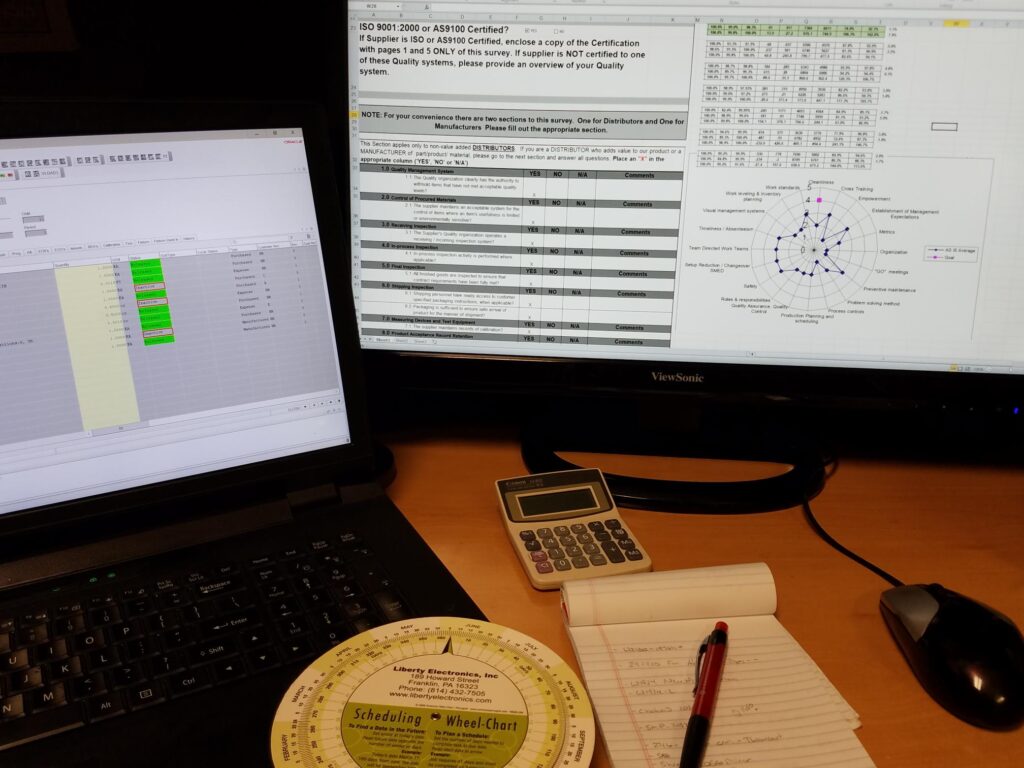

The Benefits of a Custom IT Strategy [VIDEO]

In today’s manufacturing environment, IT is an increasingly powerful tool for addressing a range of issues from cybersecurity to production and operation efficiencies. In this episode of Wired Success, Mark Cessar and Troy Funte discuss the value and benefits of remaining nimble in a constantly evolving tech landscape and utilizing catered solutions to quickly resolve issues. […]

How the Right Contract Manufacturer Benefits OEMs [Video]

Choosing the right Contract Manufacturer is integral to business success, whether taking a strategic outsourcing approach, or a tactical one. In this episode of Wired Success, Mark Cessar talks with Liberty’s Director of Business Development, Scott Anderson about how the right Contract Manufacturer can benefit your business, and how that can depend on whether the business takes a strategic approach or a tactical approach to […]

Quality Assurance In Low-Volume High-Mix Manufacturing

Read about the tools and strategies manufacturers can use to meet high quality standards in constantly changing assembly environments. Assuring quality in a low volume, high mix manufacturing environment presents some unique challenges. Often, the manufacturing process is no sooner set up then it must be disassembled to begin building an entirely different assembly; assemblers […]

Can the U.S. Become its Own Manufacturing Island? [Video]

Liberty has worked with customers previously that were not realizing the expected benefits of using an offshore supplier, but recent events have a lot more OEM’s looking to move some or all of their supply chains to the United States. The Institute for Supply Management reported last month that nearly 75% of companies are reporting supply chain […]

EMS Outsourcing Infographic

In developing standardized procurement processes, operations and purchasing decision-makers should consider strategic sourcing as a part of their procurement best practices. However, they should keep in mind that strategic sourcing is not a single project but rather a key continuous process. For those companies sincere about establishing control over their supply chains, incorporating strategic sourcing […]

Leadership in Technology: Using 3D Printing in Aerospace Part Production

Read about how Liberty Electronics has applied its expertise in 3D printing to new services for their customers. Liberty Electronics has been at the forefront of 3D printing since the technology became commercially available, and has been recognized for driving innovation in a number of areas. From developing novel applications to partnering with Stratasys in […]

The Benefits of Collaborative Design [Video]

In this episode of Wired Success, Sales Engineer, Mark Cessar, talks with George Allman, Liberty Electronics’ Manufacturing Engineering Supervisor to ask some questions about how OEMs can benefit from collaborating with suppliers during the design phase of a project. During their discussion, George shares what suppliers can bring to the table and the overall value this offers OEMs. […]

How Procurement Professionals Can Prevent Fulfillment Pitfalls

With the news of backlogs at record highs this year, industry OEMs and suppliers are looking for ways to ramp up production to meet demand. Meeting these needs can become challenging when fulfillment issues arise. According to forecast experts like Deloitte, manufacturers in 2019 should be focused on strengthening their supply chains, more effectively managing projects, […]

Overcoming Tribal Knowledge in Outsourcing

Imagine notifying your two largest customers that their lines will be down because you won’t be able to deliver their products for 16 weeks. Imagine the daily conference calls, site visits, audits, and over-time costs while your organization is turned upside down trying to deliver product, all for one simple reason: a key part of […]

Reduce Supply Chain Issues With a Relationship-Focused Supplier

Reduce Supply Chain Issues With a Relationship-Focused Supplier OEMs rely on successful partnerships to improve performance, especially when supply chain issues are top of mind for many businesses. It’s crucial to consider how successful long-term relationships can ease supply chain delays through reduced lead times and expedited problem solving. Building individualized relationships creates better access […]

Why OEMs Should Consider Outsourcing A Level Up the Bill of Material

The Bill of Material is a critical component of the planning process in manufacturing for any industry. This comprehensive list of components and equipment required to manufacture a product can fluctuate depending on cost, availability, and capacity. For original equipment manufacturers (OEMs), outsourcing a level up the Bill of Materials might prove to be beneficial. […]

Lean Manufacturing In a Low-Volume High-Mix Environment

Read about how Liberty Electronics has implemented lean manufacturing process to save its customers lead time and cost while delivering high-quality product. Implementing Lean Manufacturing in a low-volume, high-mix electronic manufacturing services (EMS) company is not a textbook exercise. Frequent customer-driven schedule changes, limited production quantities and frequent setups require some creativity in implementing lean […]

Thoughts on Liberty: Part 4: Cost

Liberty is a subject near and dear to our hearts here at Liberty Electronics. Last time, we talked a little about the start of American liberty, but what exactly is liberty? Perhaps equally important – what is it not? Join us again today as we continue to explore our “great experiment for promoting human happiness.” Last time we talked about American […]

Thoughts on Liberty: Part 3: Guard Rails

Liberty is a subject near and dear to our hearts here at Liberty Electronics. Last time, we talked a little about the start of American liberty, but what exactly is liberty? Perhaps equally important – what is it not? Join us again today as we continue to explore our “great experiment for promoting human happiness.” In this installment of our […]

Thoughts on Liberty: Part 2: Responsibility

Liberty is a subject near and dear to our hearts here at Liberty Electronics. Last time, we talked a little about the start of American liberty, but what exactly is liberty? Perhaps equally important – what is it not? Join us again today as we continue to explore our “great experiment for promoting human happiness.” Noah Webster, the prodigious 19th-century […]

Thoughts on Liberty – Part 1: Foundation

Given our name, it’s probably no surprise that we are big fans of American liberty here at Liberty Electronics. In the coming weeks and months, we will look at this interesting and relevant topic, what some notable people have had to say about it, and how those ideas guide our work ethos at Liberty Electronics. Pull up a […]

3D Printing Innovation During the COVID-19 Crisis

During this historical period of time where the world is experiencing the COVID-19 outbreak, businesses everywhere are responding with necessary measures and precautions. Stopping the spread cannot be done through maintaining the normal day-to-day functions. As social gathering has been put to an end for the time being, and humans find solace and protection in […]

How Overmolding Can Help Wires Last Longer and Perform Better

How Overmolding Can Help Wires Last Longer and Perform Better Wires frequently become strained especially when used in different temperatures and conditions. But there is a solution that can help prevent wear and lengthen the life of your wires and cables – overmolding. Molding and insulation are necessary to protect wires from wear and tear, […]

Effective Configuration Management in an Industry of Adaptability

In today’s manufacturing world, “good” is not good enough when it comes to configuration management. In our increasingly competitive, fast-paced market, change processes are vital to ensuring that you get the right components, adhere to modified critical dimensions, and have the correct code in software programs and revised tool settings; these are only a few […]

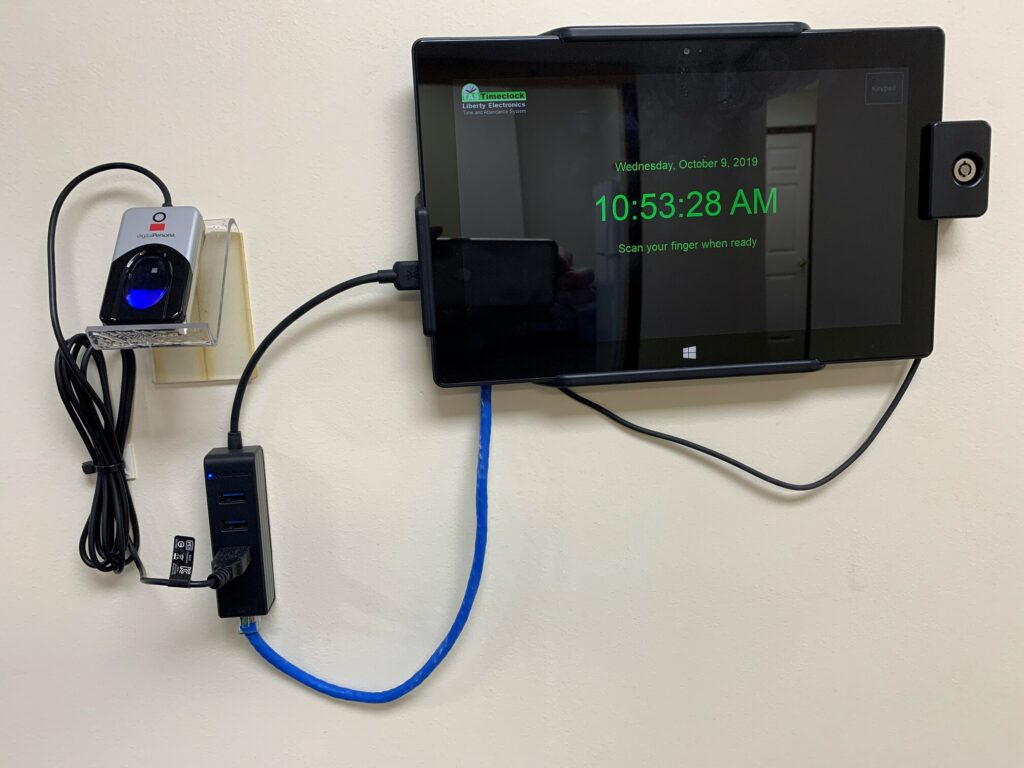

Custom IT Applications in the Manufacturing World

Information technology can promote the development and productivity of a business. That is why IT is a core competency at Liberty Electronics and plays a key role in satisfying our customers. Rather than using off-the-shelf software, which is often a “jack of all trades and master of none,” Liberty employs a different approach. In the […]

Strategic Sourcing Basics for Aerospace Manufacturers

Strategic sourcing processes allow manufacturers to choose the best vendors based on more factors than cost alone. By evaluating other characteristics such as quality management practices, efficient operations, design capabilities, and sustainability, purchasing managers are using strategic sourcing techniques to look at the “bigger picture” for long-term growth. Strategic Sourcing vs. Traditional Purchasing During the […]

Employee Culture: Staying Sharp with Continuous Training

No matter how precise a tool may be, it still needs to be honed, recalibrated, and reevaluated in order to stay in prime condition and do its job correctly. This is no different for a workforce. No matter how knowledgeable or skilled an employee may be, there are always ways for the employee to refresh […]

Safety First: How Liberty Prioritizes Safety in the Workplace

Most companies work to ensure a maximum standard of safety in a workplace environment. There are several unique ways that Liberty makes employee safety and security a priority, by getting not only employees involved, but their families as well. Workplace safety starts with aptly training the workforce, not only in day to day safety practices, […]

Solving Problems With Root Cause Corrective Action

Solving Problems With Root Cause Corrective Action When a project goes astray, one of the most important ways to get it back on track is to find out exactly what went wrong. Using supporting data and facts, root cause corrective action (RCCA) is one way to resolve the issue. The RCCA method finds and eliminates […]

Liberty, Independence, and Reshoring

In an interesting convergence, the new United States Mexico Canada Agreement (USMCA) trade deal has taken effect within days of celebrating Independence Day here in the United States of America. The new deal replaces the old North American Free Trade Agreement (NAFTA) that was implemented on January 1, 1994. While the net effect of NAFTA has been […]

How the Right Contract Manufacturer Can Benefit Your Bottom Line

Lack of capacity, along with rising operating costs and increased competitive pressures, have caused companies to explore the option of contract manufacturing for their products. Contract manufacturing outsources certain manufacturing operations to a third-party, passing on the responsibility for materials, capital, equipment, staff, and software. Contract manufacturing allows businesses to shift their focus away from […]

How to Successfully Switch Suppliers [Video]

Scott Anderson of Liberty Electronics shares best practices and the importance of a multidisciplinary team in the process of switching suppliers. This includes ensuring adequate production capacity, consistent OTD, and dual-sourcing supply to avoid supply chain disruption. To learn more about how Liberty works with customers on supply chain management and switching suppliers, check out our […]

Advantages of Moving Up the Bill of Materials [Video]

The Bill of Material is a critical component of the planning process in manufacturing for any industry. In this episode of Wired Success, Mark Cessar talks with Liberty’s Programs Director, Troy West about what moving up the Bill of Materials is and how this approach to procurement can benefit OEMs in terms of ease of installation, capacity, costs, and inventory reduction. […]

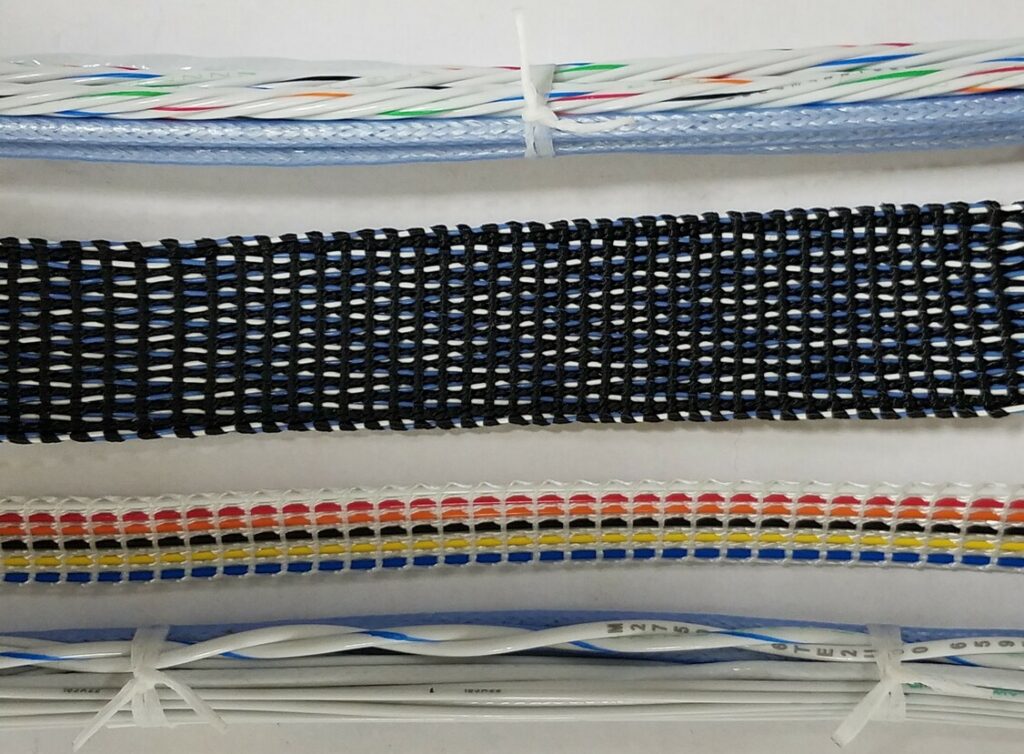

Wire Braiding: Machine Versus Premade Options

Braided coverings and shieldings are an excellent way to make wiring configurations neat and uniform. Braiding gives wires more flexibility and a longer lifespan and can also offer a layer of electric protection or abrasion resistance. Although there are two different types of wire braiding widely used in the industry, machine braiding and premade (or slide-on) braiding, […]

Understanding Insulation Materials

Insulation materials provide wiring harnesses with a layer of necessary protection in a variety of ways, depending on the specific requirements the product must meet. Insulation helps protect the product mechanically, electrically, or environmentally, meeting particular needs according to the product’s application. Additionally, a variety of materials used in wiring harness insulation ensure the various […]

COVID-19 Update

As noted previously, Liberty Electronics has remained open as an essential business. We are under Federal mandate to work on all Department of Defense related contracts according to the rating systems priorities. Average labor availability for the current week has been slightly below normal expectations. The coming weeks and months may see increased variation in the […]

Liberty Electronics Announces Purchase of State-Of-The-Art Production Facility in Pennsylvania

FRANKLIN, PA, OCT 28, 2020 – Liberty Electronics is pleased to announce the purchase of an additional state-of-the-art production facility in Franklin, PA. This facility had been leased by Liberty previously, but the purchase includes 56 acres to support future expansion plans. The purchase has also enabled Liberty to invest in a significant upgrade to the […]

Benefits of a Relationship-Minded Supplier [Video]

Driving performance through successful partnerships is a critical component of the OEM supply chain. Liberty prides itself on being a relationship-minded supplier, knowing the ins and outs of our OEM partners. Quick resolutions and proactive awareness of potential order issues, faster turnaround times for new orders, as well as a deep familiarity with product lines […]

COVID-19 Update

As noted previously, Liberty Electronics has remained open as an essential business. We are under Federal mandate to work on all Department of Defense related contracts according to the rating systems priorities. While stay at home orders are in effect in places around the globe, we continue to engage with the supply chain to maximize […]

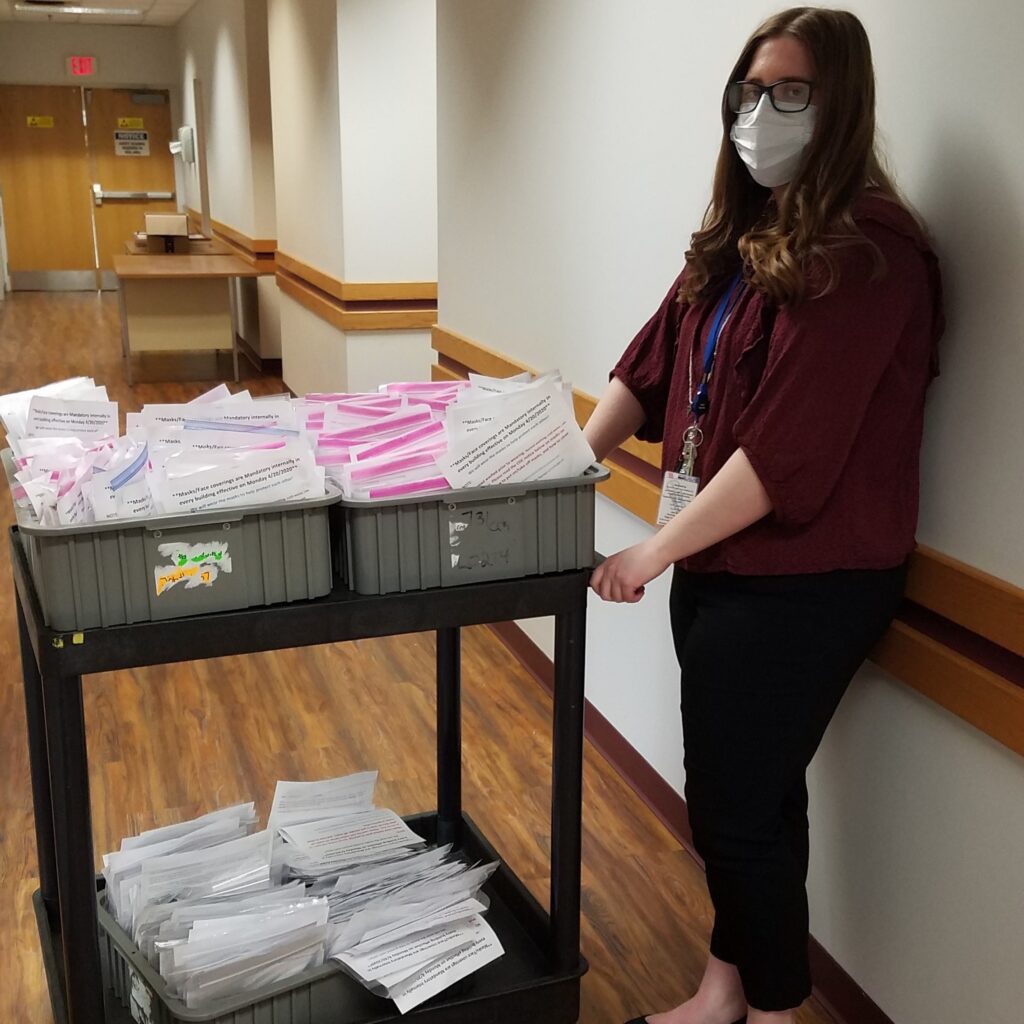

Please, Put Your Mask On Before Helping Others

As our world continues to navigate the COVID-19 health crisis, countries’ efforts to quarantine and isolate are taking effect to protect their citizens. We are seeing the curve begin to flatten in countries, with some reopening with no signs of the virus altogether. The United States continues to make health decisions state by state, with […]

Keeping Employees Safe with 3D Printing

During this historical period of time where the world is experiencing the COVID-19 outbreak, businesses everywhere are responding with necessary measures and precautions. Stopping the spread cannot be done through maintaining the normal day-to-day functions. As social gathering has been put to an end for the time being, and humans find solace and protection in […]

2021 Industry Outlook – Aerospace & Defense

Liberty Electronic’s Industry Outlook series analyzes the market for trends suppliers at all levels of the supply chain should watch. In this installment, we break down Aerospace and Defense trends. With a difficult 2020 behind us, this year’s relaxed COVID-19 restrictions herald the airline industry’s long road to recovery with returning travel. Though the commercial […]

Open Lobby Night for Manufacturing

FOR IMMEDIATE RELEASE Liberty Electronics to Host Open Lobby Night for Manufacturing Day on October 4th, 2019 for the local community Franklin, PA — Liberty Electronics, a manufacturer of electronic wiring harnesses, cable, cabinet, panel and electromechanical assemblies, will be celebrating Manufacturing Day 2019 by hosting an event at their facility. The open lobby night […]

Community and Beyond: The Global Impact of Liberty Electronics

Every community is impacted by the companies that operate within. Companies of all sizes create a ripple effect, creating a variety of touchpoints and connections within their communities and beyond. This is especially true of a company like Liberty Electronics. Although a small business by definition, Liberty is actually one of the largest companies in […]

Special Delivery: Boxing and Shipping

Creating a quality product doesn’t just end with the manufacturing phase. Choosing the best packaging and shipping options to meet a client’s needs is also an important step in ensuring a product reaches the client in the same state it left the facility. Components are packaged according to specific standards and or client guidelines, and […]

Our Start Part 5: Full Circle

The autumn of 2001 found Liberty Electronics’ employees full of confidence in the future. Years of developing strong customer relationships and providing high quality products had solidified Liberty’s reputation within the manufacturing community. The company had built on this foundation by attaining the International Standard Certification ISO9001 three years previously, shifting from a narrow focus […]

Our Start Part 4: Moving Forward

Great accomplishments often have small beginnings, an idea with which Liberty Electronics is more than familiar. Once a business concept found only on paper for a university research project, by the early 1990s Liberty was a fully formed corporation coming into its own. The company had deliberately focused on defense programs since its 1986 founding, […]

3D Printing: Ergonomic Benefits in Productivity

In the nearly five years since Liberty Electronics has utilized 3D printing in its manufacturing processes, the company has not only increased offerings to its clients, but also improved the lives and careers of its own employees. Through the use of additive manufacturing to provide worker accommodations, Liberty has solved several common problems relating to accommodations and disabilities in […]

Safety in Numbers: How Process Metrics and Certification Drive Quality

Recently, the Washington Metro Area Transit Authority (WMATA) in the nation’s capital was forced to decommission nearly 75% of its new 7000-series rail cars due to crimping defects. The rail cars had crimping defects that went undetected until WMATA’s quality inspectors discovered them. The WMATA’s Quality Assurance, Internal Compliance and Oversight office (QICO), estimates that the rail cars […]

Our Start Part 3: Integrity

In the spring of 1986, Liberty Electronics could look back on a wildly successful year. Its founders had taken the company from a research project to a living, breathing corporation. The community of Franklin, Pennsylvania, rose to the occasion to make this innovative new enterprise welcome, through financial backing and filling production team roles. Work […]

Our Start Part 2: Investment

After a pell-mell race to form a company, choose a site, and secure financing, Liberty Electronics started the new year of 1986 enthusiastically readying its Franklin building and marketing its products. The founders envisioned an innovative company working in state-of-the-art facilities to produce much-needed cable and wiring assemblies for military and commercial industries. They had […]

Our Start Part 1: Innovation

The morning of February 17, 1986, dawned cool and rainy in Franklin, Pennsylvania. Despite the chill in the air and the fog hovering over French Creek, there was an undercurrent of excitement. After months of intense pressure, tight deadlines, and hundreds of man-hours of work, Liberty Electronics, the town’s newest business, was set to open […]

Liberty Electronics Becomes a HUBZone Certified Small Business

As of June 15, Liberty Electronics became certified as a HUBZone Small Business Concern. The HUBZone (Historically Underutilized Business Zone) program is offered through the U.S. Small Business Administration (SBA). The program seeks to promote small business growth in distressed areas by increasing employment opportunities and investing in economic development. Liberty’s participation in the program […]